Pulling Ropes

Pulling Ropes "Performance Series" (Braided Steel)

Our braided steel wire ropes are torsion-free because they are made of equal numbers of left and right winding wire strands. This makes them the perfect choice for conductor stringing with double capstan pullers.Our wire ropes are made of high-quality strands supplied by the world's leading wire rope manufacturers. The properties of our wire rope combine long endurance with high tensile strength. The strands are individually lubricated and manufactured in strict compliance with European Standards.

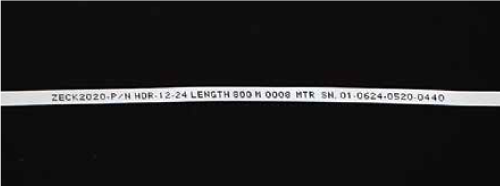

*Image : including optional marking tape

| part no. | ZECK GmbH part no. |

dia mm. |

SWL kN |

min BL kN |

weight kg/m |

standard length m** |

max. length with reel dia. | ||

| 1,100 mm | 1,400 mm | 1,800 mm | |||||||

| SWR-12-08 | 60-1008 | 8 | 17 | 50 | 0.23 | 1600 | 3200 | 6400 | 12800 |

| SWR-12-10* | 60-1010 | 10 | 24 | 72 | 0.33 | 1000 | 2000 | 4000 | 8000 |

| SWR-12-11 | 60-1011 | 11 | 28 | 85 | 0.39 | 800 | 1600 | 3200 | 6400 |

| SWR-12-12 | 60-1012 | 12 | 37 | 110 | 0.49 | 1400 | 1400 | 2800 | 5600 |

| SWR-12-13* | 60-1013 | 13 | 38 | 115 | 0.56 | 1200 | 1200 | 2400 | 4800 |

| SWR-12-14 | 60-1014 | 14 | 42 | 127 | 0.68 | 1000 | 1000 | 2000 | 4000 |

| SWR-12-16* | 60-1016 | 16 | 57 | 170 | 0.81 | 800 | 800 | 1600 | 3200 |

| SWR-12-18* | 60-1018 | 18 | 72 | 215 | 1.10 | 1200 | - | 1200 | 2400 |

| SWR-12-20* | 60-1020 | 20 | 90 | 270 | 1.35 | 1000 | - | 1000 | 2000 |

| SWR-12-22* | 60-1022 | 22 | 107 | 320 | 1.52 | 900 | - | 900 | 1800 |

| SWR-12-24* | 60-1024 | 24 | 120 | 360 | 1.80 | 800 | - | 800 | 1600 |

| SWR-18-27 | 60-1027 | 27 | 153 | 460 | 2.29 | 600 | - | 600 | 1200 |

| SWR-18-29 | 60-1029 | 29 | 179 | 536 | 2.59 | 500 | - | 500 | 1000 |

| SWR-18-32 | - | 32 | 220 | 660 | 3.22 | 400 | - | 400 | 900 |

*produced on stock

** other lengths available upon request

working loading is calculated according to European standards (safety factor : 3.00)

Optional Equipment:

| part no. | ZECK GmbH part no. | description |

| SWR-00-01 | 60-1000 | marking tape, indicating serial #, part #, length and manufacturing month/year |

Pulling Ropes "Ultimate Series" (Braided Steel)

| Our unique heavy duty HD ropes are now classified with a name that better reflects their exceptional properties: Ultimate Ropes. The strands of these ropes are compacted, resulting in significantly less friction within and between strands. This shifts the focus of their properties to the two factors that really matter: strength and durability. The surface of the compacted strands is smoothened, which minimizes the likelihood of them climbing out of the pulley sheaves, especially under angled pulls. The higher breaking load of the Ultimate rope is achieved without an increased carbon content of the steel, thereby not sacrificing endurance in favor of breaking strength. |

|

|

| part no. | ZECK GmbH part no. |

dia. mm |

SWL kN |

min BL kN |

weight Kg/m |

standard length m** |

max. length with reel dia. | ||

| 1,100 mm | 1,400 mm | 1,800 mm | |||||||

| HDR-12-07 | - | 7 | 17 | 50 | 0.25 | 1600 | 3200 | 6400 | 12800 |

| HDR-12-09 | - | 9 | 24 | 72 | 0.34 | 1000 | 2000 | 4000 | 8000 |

| HDR-12-10 | 60-1010HD | 10 | 28 | 85 | 0.42 | 1000 | 2000 | 4000 | 8000 |

| HDR-12-11 | 60-1011HD | 11 | 37 | 110 | 0.50 | 800 | 1600 | 3200 | 6400 |

| HDR-12-12 | 60-1012HD | 12 | 38 | 115 | 0.64 | 1400 | 1400 | 2800 | 5600 |

| HDR-12-13 | 60-1013HD | 13 | 42 | 127 | 0.70 | 1200 | 1200 | 2400 | 4800 |

| HDR-12-14 | - | 14 | 57 | 170 | 0.80 | 1000 | 1000 | 2000 | 4000 |

| HDR-12-16 | 60-1016HD | 16 | 72 | 215 | 1.01 | 800 | 800 | 1600 | 3200 |

| HDR-12-18 | 60-1018HD | 18 | 90 | 270 | 1.19 | 1200 | - | 1200 | 2400 |

| HDR-12-20 | - | 20 | 107 | 320 | 1.56 | 1000 | - | 1000 | 2000 |

| HDR-12-22 | 60-1022HD | 22 | 120 | 360 | 1.74 | 900 | - | 900 | 1800 |

| HDR-12-24 | 60-1024HD | 24 | 153 | 460 | 2.11 | 800 | - | 800 | 1600 |

| HDR-18-27 | 60-1027HD | 27 | 179 | 536 | 2.61 | 600 | - | 600 | 1200 |

| HDR-18-29 | 60-1029HD | 29 | 220 | 660 | 3.17 | 500 | - | 500 | 1000 |

| HDR-18-32 | - | 32 | 240 | 720 | 3.79 | 400 | - | 400 | 800 |

| HDR-18-36 | - | 36 | 267 | 800 | 4.21 | 300 | - | 300 | 700 |

working loading is calculated according to European standards (safety factor : 3.00)

Optional Equipment:

| part no. | ZECK GmbH part no. | description |

| SWR-00-01 | 60-1000 | marking tape, indicating serial #, part #, length and manufacturing month/year |

|

|

| including steel reel |